Maybe you’ve already seen a video or listened to a podcast explaining how ancient civilizations across the arid lands of the Middle East have long used terracotta structures with water to create efficient evaporative cooling solutions, systems that neither require electricity nor create an iota of emissions. Large installations such as Ant Studio’s large natural air cooler have been built to showcase how the porous material paired with water can cool surrounding air by the process of evaporation, especially of interest across our dangerously warming planet.

But what about applying the same idea on a smaller scale, one suitable for a house or just a room? Simon Pavy and design agency Entreautre have set out to use that same principle in the form of a small vessel, using a customized 3D printer to create the Biomimcry 3D-Printed Terracotta Cooler.

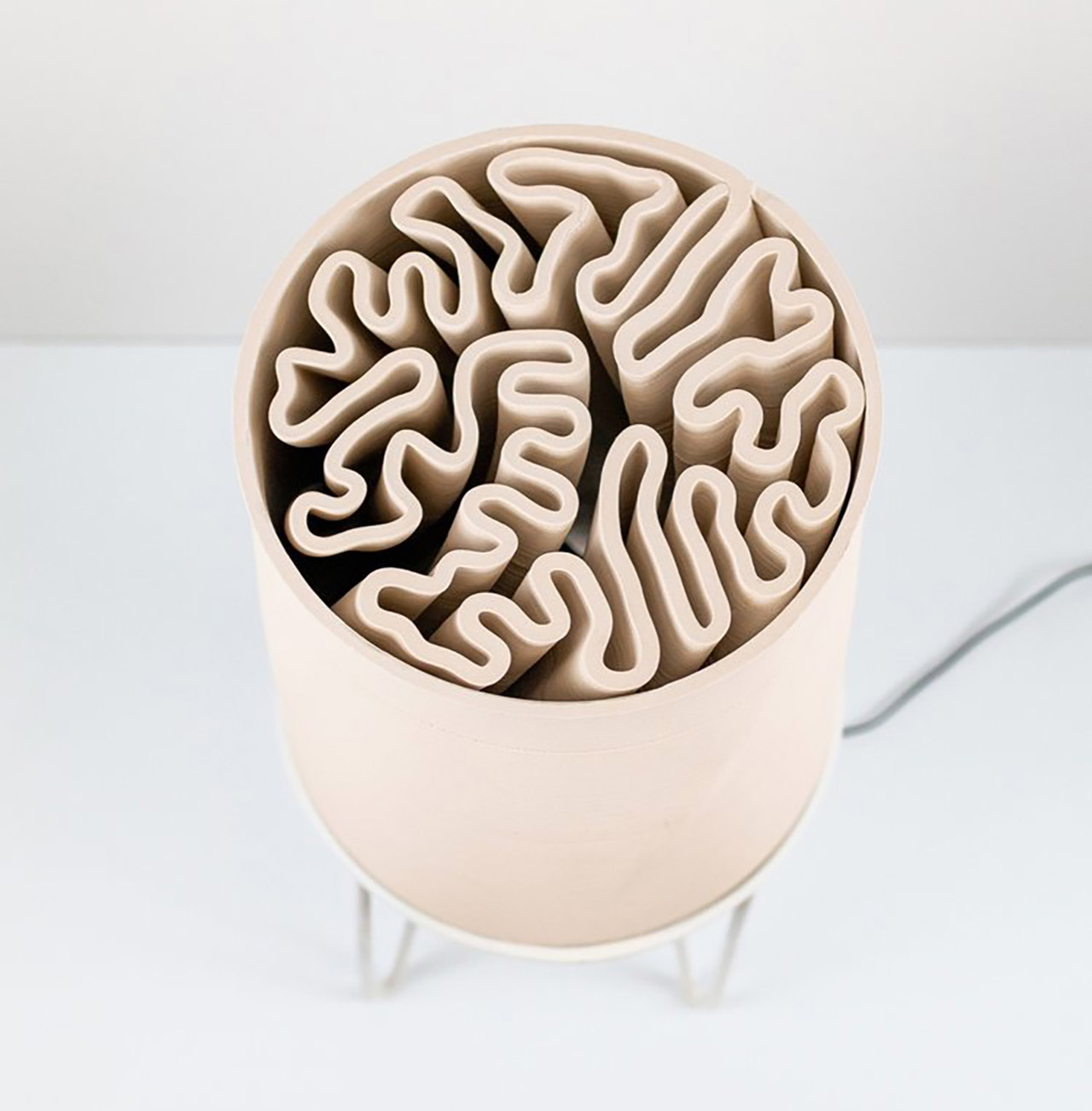

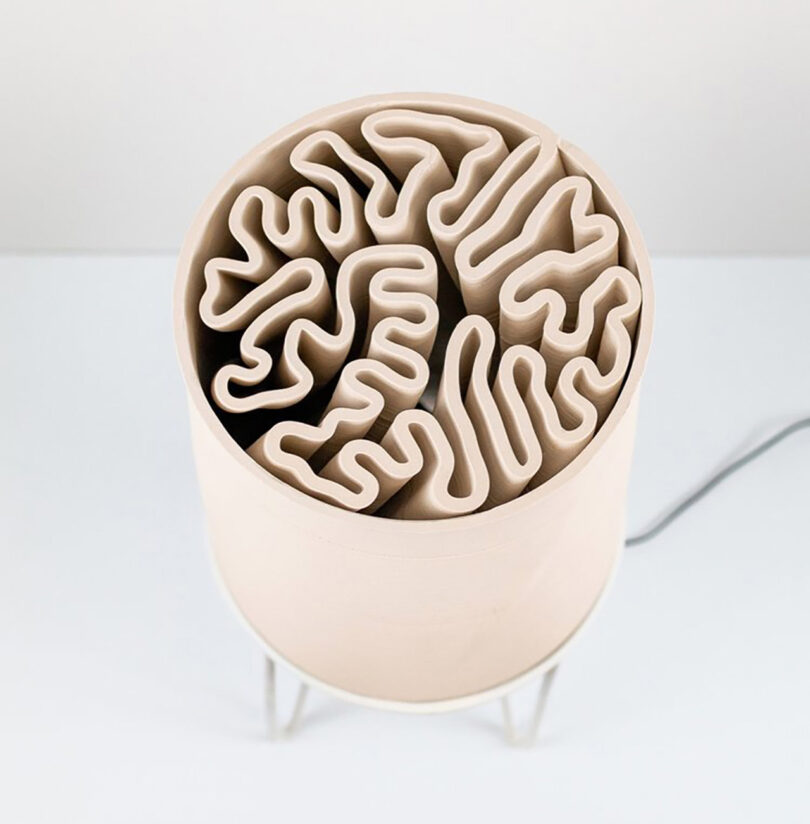

Within a ceramic vessel no larger than a typical houseplant planter lies the secret of the Biomimcry’s cooling qualities: an intricate nest of looping volumes inspired by coral. The vessel is manufactured layer by layer using a special 3D printer customized by Dutch artist, Olivier Van Herpt. Instead of typical plastic filament fueling output, Van Herpt’s printer extrudes terracotta in filaments with the precision of a skilled pastry chef using a fine-tipped icing bag.

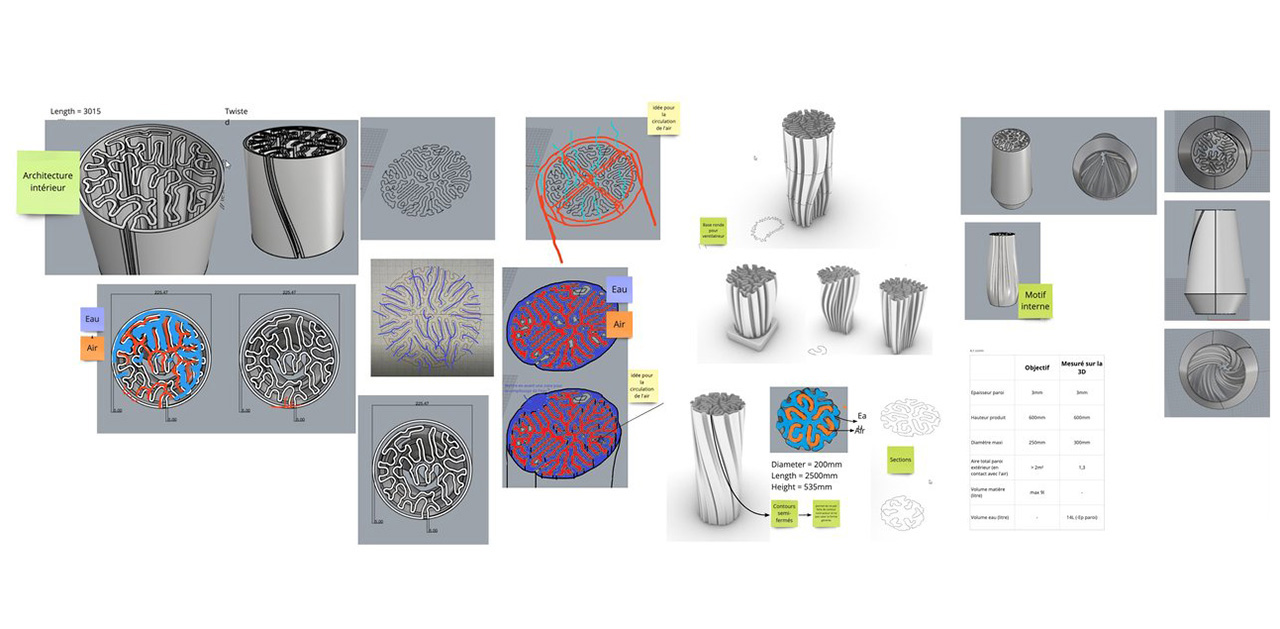

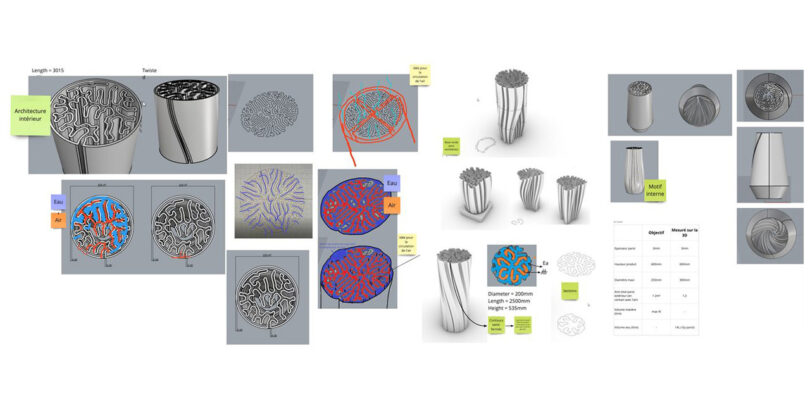

The 3D printer has unlocked biomimetic geometries impossible to achieve by traditional manual techniques.

The coral-inspired form increases surface area where water can evaporate, and in turn, cool ambient air. The process is aided with a modern technological accomplice: a fan. Alongside the aid of an electric fan positioned at the bottom of the vessel, the evaporative effect is magnified by the layered coils’ finely ridged texture, a physical characteristic created during the 3D-printing process itself. In this way the technical constraint of 3D printing has become both an aesthetic signature of the object and an efficacy enhancer.

“I designed this structure using the software Grasshopper,” says designer Simon Pavy, “Which is a visual 3D programming language connected to Rhino 3D. It enables the creation of intricate and parametric components that would be challenging to achieve with conventional CAD programs.”

The Biomimcry 3D-Printed Terracotta Cooler still has some ways to go to make the jump from concept to a readily available product. But creator Pavy says the project is planned to launch in an industrial version as early as 2024 upon graduating from its current testing phase.